So, what are these "biodegradable alternatives" we keep hearing about? At its heart, it's pretty simple. We’re talking about materials, often made from plants like corn, sugarcane, or even mushrooms, that are designed to break down and return to the earth naturally.

Think of it as a complete opposite to traditional plastic, which can haunt our planet for literally centuries. These options give beauty brands—and all of us who buy their products—a way to massively cut down on packaging that sticks around forever.

The Urgent Search for Plastic Alternatives

It doesn’t take a scientist to see we have a plastic problem. Just look around. The beauty industry alone creates a truly staggering amount of plastic packaging every year, and sadly, most of it never even sees a recycling bin.

This isn’t just ugly; it’s dangerous. This waste chokes our landfills, floods our oceans, and crumbles into nasty microplastics that poison entire ecosystems. Let’s be real: the environmental price tag for our convenience has gotten way too high.

This guide is your map through the sometimes confusing world of biodegradable plastic alternatives. We'll cut through the greenwashing noise and the jargon to show you what’s actually doable for your brand.

Why This Is a Big Deal Right Now

Moving away from old-school plastic isn't just a "nice to have" anymore; it’s a must-do, driven by a few powerful truths:

- Shoppers are demanding it. More and more, people are voting with their wallets for brands that show they genuinely care about the planet. Your packaging is often the first thing they see—it’s a huge signal of what your company stands for.

- The rules are changing. Governments all over the world are cracking down on single-use plastics. Getting ahead of these new laws isn't just good for the earth, it's just smart business.

- Your reputation is on the line. In a sea of options, sustainability makes you stand out. Brands leading the charge with eco-friendly packaging are building way more trust and loyalty with their customers.

This is a conversation, not a lecture. Our goal is to dig into the materials, the real-world hurdles, and the practical steps your brand can take to make a real, positive dent in the problem.

We'll start with the basic science and work our way up to navigating supply chains and making choices that feel good for both your business and your conscience. By the time you're done here, you’ll have the clarity to move your packaging strategy forward with confidence—armed with actual knowledge, not just good intentions. This is about progress, not perfection, and it all starts with understanding what’s possible.

Decoding the Language of Sustainable Materials

Diving into the world of plastic alternatives can feel like trying to learn a new language. You’ll hear words like "biodegradable," "compostable," and "bio-based" thrown around constantly, often as if they all mean the same thing. But they don't. This confusion is where well-meaning brands and customers can make mistakes, so let's clear things up.

Think about an apple core. If you toss it in your backyard, it's truly biodegradable. Microbes and fungi will go to work, breaking it down naturally over time until it returns to the soil. No special equipment needed.

The problem is, many "biodegradable" plastics are nothing like an apple core. The term itself is super vague and often unregulated. It just means something can be broken down by living organisms, but it says nothing about how long it will take (could be decades!) or what conditions are required.

Compostable: A Real, Measurable Promise

This is where the word compostable becomes incredibly important. A compostable material is a very specific type of biodegradable material. It comes with a guarantee.

Picture a high-tech pressure cooker. That’s essentially what an industrial composting facility is for these materials. It provides the perfect storm of intense heat, moisture, and microbes needed to break everything down into non-toxic bits—usually within 90 to 180 days.

Compostable isn't just a marketing buzzword; it's a performance standard. To earn that label, materials have to be certified to prove they'll break down safely in a specific timeframe, leaving behind healthy compost, not nasty residues.

So, that "compostable" coffee lid? If it ends up in a landfill or the ocean, it might as well be regular plastic, sticking around for years. It needs the right facility to fulfill its promise. For a deeper look at how these materials work in practice, check out our guide on eco-friendly packaging for cosmetics.

Bio-Based: It’s All About the Origin Story

Finally, there’s bio-based. This term tells you where a material comes from, not where it ends up. A bio-based material is made, in whole or in part, from renewable stuff like corn, sugarcane, or algae instead of finite fossil fuels.

Here’s the catch: a material can be bio-based but not biodegradable. Some companies make durable plastics from sugarcane that are chemically identical to petroleum-based plastic. They help us rely less on oil, which is great, but they still need to be recycled, not composted.

On the flip side, some fossil-fuel-based plastics can be designed to be biodegradable. The key is to always look at both the source and the end-of-life plan.

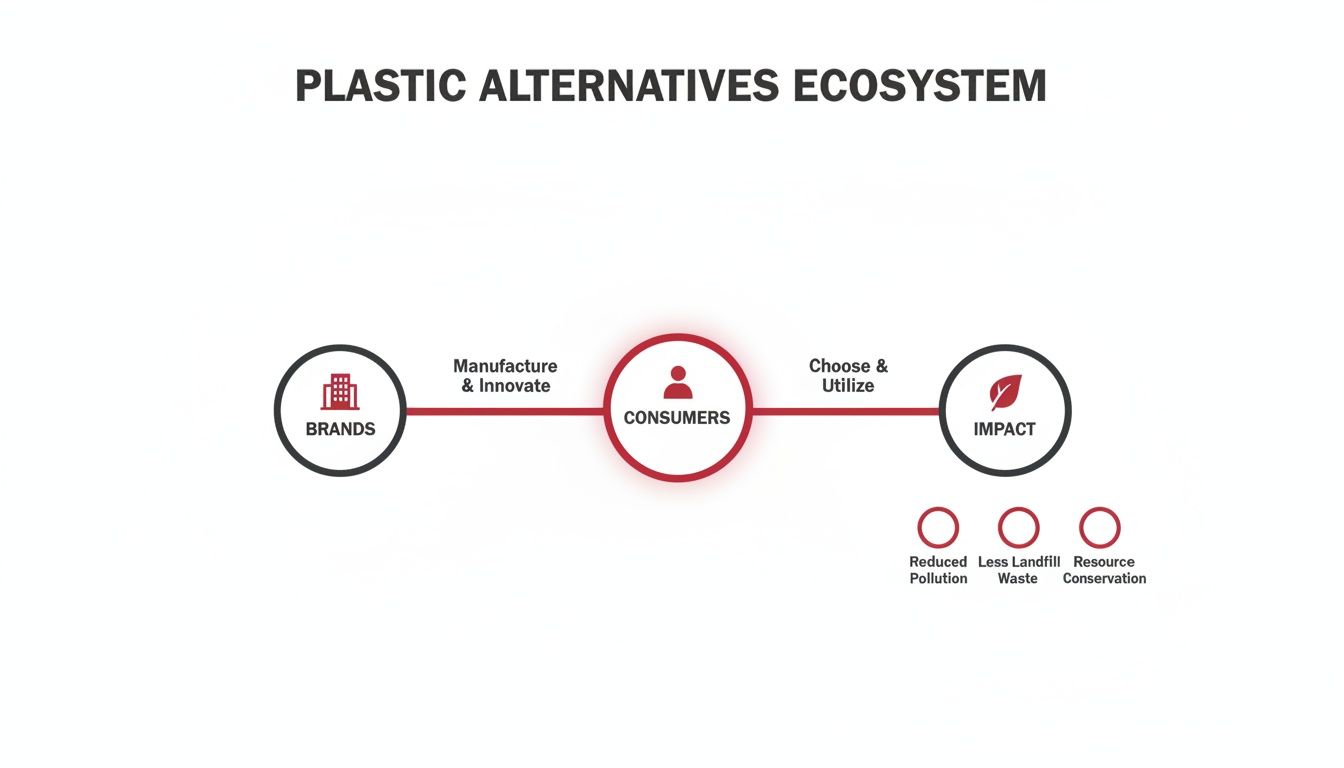

This whole system is a connected loop. The choices brands make impact how consumers dispose of products, which ultimately determines whether the environmental outcome is good or bad.

To make it even clearer, I've put together a quick cheat sheet to help you tell these terms apart.

Decoding Sustainable Material Terminology

| Term | What It Means | Common Source Material | Required End-of-Life |

|---|---|---|---|

| Biodegradable | Will eventually break down by natural processes. But the timeline and conditions are not guaranteed. | Can be plant-based or fossil-fuel-based. | Varies wildly; may not break down properly in landfill or nature. |

| Compostable | A certified promise that it will break down into non-toxic components within a set time under specific conditions. | Usually plant-based (e.g., PLA from cornstarch). | Requires industrial or home composting facility access. |

| Bio-Based | Made partly or wholly from renewable biological resources, like plants. | Corn, sugarcane, algae, bamboo. | Varies; can be recyclable, compostable, or neither. |

Knowing this vocabulary is your best defense against greenwashing. It empowers you to ask the right questions: What’s this made from? And, just as important, how do I get rid of it properly? Getting that clarity is the only way to ensure the sustainable alternatives we choose actually live up to their eco-friendly promise.

Diving Into the Top Biodegradable Materials

The world of plastic alternatives is buzzing with some seriously cool science. We're talking about turning everyday plants and even fungi into real, viable packaging. These aren't just lab experiments anymore; they're tangible solutions that are ready to reshape how we think about packaging, especially in the beauty world.

So, let's meet the main players. Each has its own origin story, its own set of skills, and its own best role in the fight against plastic waste.

PLA: The Clear Workhorse

When people first dip their toes into bioplastics, PLA (or Polylactic Acid) is usually the first material they meet. Think of it as the versatile, popular kid in class. It’s typically made from fermented starches from renewable crops like corn, sugarcane, or cassava.

The biggest plus for PLA is that it looks and feels a lot like conventional PET plastic. It can be molded into clear containers, jars, and films, which makes it a go-to for product packaging where you want to see what's inside.

But PLA isn’t perfect. It has a pretty low tolerance for heat, so it’s not great for products that might sit in a warm bathroom or mailbox. And its biggest hurdle, as we've mentioned, is that it needs a special industrial composting facility to actually break down.

- Best For: Clear jars for creams, boxes with see-through windows, and single-use items.

- Keep in Mind: Not for hot-fill products. It absolutely requires specific disposal to avoid just becoming more landfill trash.

PHA: The Marine-Friendly Innovator

If PLA is the popular kid, PHA (Polyhydroxyalkanoates) is the brilliant, adaptable scientist of the group. Unlike PLA’s more industrial fermentation process, PHAs are made by microorganisms. Yep, bacteria. When certain bacteria are fed oils from crops like canola, they naturally produce these polymers inside their cells as an energy reserve.

This unique origin story gives PHA a superpower: it can biodegrade in a much wider range of environments, including soil, freshwater, and even the ocean. This is huge. It makes PHA one of the most exciting alternatives because it offers a potential answer to plastic pollution in our oceans.

PHA is also more flexible and durable than PLA, acting more like the traditional polypropylene plastic you see everywhere. This opens the door for everything from flexible films to straws and containers that need a little more toughness. The catch? It's currently more expensive to produce than PLA, but thankfully, those costs are coming down as the technology gets better.

Mycelium: The Fungi-Powered Protector

Okay, now for something completely different. Mycelium isn't a plastic at all—it's the root structure of mushrooms. To make packaging, agricultural waste like hemp or corn husks gets packed into a mold and then inoculated with mycelium spores.

Over just a few days, the mycelium grows, weaving through the waste and binding it all together into a solid, lightweight form. The final piece is gently heated to stop the growth, and voilà: you have a material that is 100% natural and home compostable.

Mycelium packaging is like nature’s own Styrofoam. It’s perfect for protective inserts that cushion fragile items like glass cosmetic bottles during shipping, offering a truly regenerative alternative to polystyrene.

Its rustic, earthy look makes it a no-go for primary product containers, but it's a brilliant choice for secondary packaging where protection and a bold sustainability message are the main goals.

This shift from niche lab creations to a real industrial market is happening fast. Global production for biobased plastics is projected to roughly double to 4.69 million tonnes by 2030. This growth is being led by materials like PLA and PHA, with packaging already making up over 41% of the bioplastics market. It’s proof that these alternatives are ready for prime time.

While these materials hold incredible promise, it's crucial to remember they are tools, not magic wands. Their success is totally tied to how they're used and, most importantly, how they're thrown away. For any brand looking to make the switch, understanding the specific needs of each material is step one. For a closer look at this, our guide on biodegradable packaging for cosmetics has more practical tips.

And the innovation doesn't stop with packaging. The ideas behind these materials are popping up in all sorts of industries. To see how these concepts are changing the game in fashion, check out this piece on the top biodegradable clothing materials. By understanding what makes each alternative unique, brands can make smarter, more effective choices that are actually better for the planet.

Navigating the Real-World Challenges and Trade-Offs

Switching to biodegradable packaging isn't as easy as just swapping out one material for another. It's a journey filled with tough questions and tricky trade-offs that every responsible brand needs to think through. This isn’t about finding some magic-bullet solution, because one doesn't exist. It’s about making a clear-eyed, informed choice that actually minimizes harm.

The whole thing is made more complicated by a landscape riddled with "greenwashing," where vague claims like "eco-friendly" or "earth-kind" can mislead even the most well-intentioned brands and shoppers. To really make a difference, we have to look past the marketing hype and into the full life cycle of these materials—from how they’re made to where they ultimately end up.

Cutting Through the Greenwashing with Certifications

One of the best ways to fight misinformation is with third-party certifications. These aren't just fancy logos; they represent rigorous, science-backed standards that actually verify a material's claims. Think of them as a background check for your packaging.

When you see these certifications, it means a material has been independently tested and proven to break down under specific conditions, all without leaving nasty toxins behind.

- BPI (Biodegradable Products Institute): This is the leading authority in North America for compostable products. The BPI logo is your guarantee that an item will break down safely in a commercial composting facility.

- TÜV Austria (OK compost INDUSTRIAL / HOME): This European certification is recognized all over the world. It makes a key distinction between materials needing an industrial facility (OK compost INDUSTRIAL) and the rarer few that can safely break down in your backyard compost bin (OK compost HOME).

Relying on certifications is your best defense against empty promises. If a supplier can't provide proof from a respected body like BPI or TÜV Austria, it’s a major red flag that their material may not perform as advertised.

The Hidden Environmental and Ethical Trade-Offs

Even with the right certifications, the story isn’t over. Choosing biodegradable alternatives forces us to confront some uncomfortable but super important questions about their wider impact.

A classic example is the "food vs. fuel" dilemma. Many bioplastics, like PLA, are made from corn. This brings up a critical question: is the land used to grow crops for packaging competing with land needed to grow food for people? As demand for these materials grows, brands have to consider the ethics of their supply chains and look for materials sourced from non-food crops or agricultural waste to avoid this conflict.

Another huge issue is the end-of-life reality. What happens if a certified compostable container ends up in a landfill, where most of our trash goes? Without the oxygen and high heat of a composting facility, it can't break down properly. Instead, it might decompose anaerobically and release methane, a greenhouse gas far more potent than carbon dioxide. This means a material designed for good can end up causing harm if the right disposal system isn't available and consumers aren't educated.

Facing the Business Realities

Beyond the environmental ethics, there are practical business hurdles to clear. The cost of these materials is often higher than conventional plastic, which can be a real barrier for small or new brands. This price gap is getting smaller, but it’s still a key thing to think about when budgeting and setting product prices.

Supply chain stability can also be a challenge. While the market for these materials is growing, it's still way less mature than the massive, established petroleum plastic industry. This can mean longer lead times, fewer supplier options, and the need for more careful planning to avoid running out of stock.

Finally, you have to rigorously test how the material performs. Will a PLA jar protect a sensitive cream from light and air? Can a mycelium insert survive a rough shipping journey? Making sure the chosen alternative actually protects the product is non-negotiable.

Despite these challenges, the momentum is undeniable. The United States market for biobased biodegradable plastics, for instance, was estimated at around $2.3 billion in 2025 and is projected to more than double to $5.5 billion by 2035. This growth is being driven by new regulations and strong consumer demand for sustainable options. You can check out the full market analysis from Future Market Insights to explore more data on this trend.

The point isn't to discourage you, but to arm you with the awareness needed to navigate the complexities and make a choice that is both responsible and realistic.

Let's Talk Market Realities and Cost

For any beauty brand thinking about making the switch to sustainable packaging, the conversation always lands on two things: cost and availability. It’s just practical. As much as we all want to do the right thing for the planet, the numbers have to work for a business to stay afloat.

The good news? The whole economic picture for biodegradable alternatives to plastic is changing, and fast. For a long time, these materials were seen as a super-niche, premium option with a price tag that made your eyes water. That’s just not the full story anymore. As more people get on board and the technology gets better, the cost gap between bioplastics and their old-school, petroleum-based cousins is getting smaller and smaller.

What's Making Sustainable Materials More Accessible?

It's not just one thing—it’s a bunch of powerful forces all working together to make biodegradable materials a real, viable option for brands of every size.

- Economies of Scale: It's simple supply and demand. As more brands start using materials like PLA and PHA, manufacturers are making way more of it. That increased volume brings the cost down for everyone.

- Volatile Oil Prices: Remember, traditional plastics are made from petroleum. When global events make oil prices go wild, the cost of making that plastic container skyrockets, too. Bio-based materials, which come from more stable sources like corn, offer pricing that’s a lot more predictable.

- Government Incentives and Regulations: Lots of governments are now actively pushing brands away from single-use plastics. They might offer grants to companies using greener materials or slap taxes on conventional plastics. Either way, it helps level the playing field.

Thinking about biodegradable packaging isn't just an "eco" decision anymore; it’s becoming a smart business move. The payoff isn't just in feeling good—it's in building brand loyalty, staying ahead of regulations, and creating a supply chain that isn't so easily rattled.

A Global Shift is Happening

This isn't just a local trend; it's a worldwide thing, even if some places are moving faster than others. The market for these materials is set to explode.

One analysis I saw estimated the global biodegradable plastics market at $5.36 billion in 2025 and projected it to shoot up to an incredible $19.41 billion by 2034. That's a growth rate of over 15% a year! It shows that investors and the industry are taking this seriously. You can see more insights on the biodegradable plastic market from Precedence Research.

When you look at different parts of the world, you can see the story unfold. Europe is leading the pack right now, mostly because of strict government rules. But keep an eye on the Asia-Pacific region—it’s expected to be the fastest-growing hub over the next decade. Why? They're beefing up manufacturing, have tons of resources like corn and sugarcane, and are facing their own internal pressure to deal with plastic waste. All this global growth means a more stable and competitive supply chain for brands everywhere.

Alright, let's turn this knowledge into action. Knowing the difference between bio-based and biodegradable is one thing, but actually making the switch is where the real impact happens. For beauty brands ready to ditch conventional plastic, it all starts with asking the right questions and ends with bringing your customers along for the ride.

Think of this as your playbook for a meaningful shift.

The first step is always the most important one: finding the right partners. You’re not just looking for a supplier, you’re looking for a collaborator who is completely transparent about their entire process. The quality and integrity of your packaging depend on it.

Vet Your Suppliers Like You Mean It

When you're talking to potential suppliers, treat it like an interview. You need to arm yourself with questions that cut through the greenwashing fluff and get to the stuff that actually matters. A partner worth their salt will welcome the scrutiny and have the answers ready.

Here’s what you absolutely have to ask:

- Can I see your certifications? Ask for proof of real certifications like BPI or TÜV Austria. Vague claims like "eco-friendly" are just noise; you need verifiable, third-party validation.

- Where does your feedstock come from? Get specific about where they source their raw materials. Are they using corn that competes with food supplies, or are they using agricultural waste? This question helps you avoid accidentally trading one environmental problem for another.

- What's the performance data? You need the technical specs. Ask about heat tolerance, moisture barriers, and shelf life to make sure the material is actually a good fit for your specific products.

The most sustainable material in the world is useless if it ends up in the wrong place. Your job doesn’t end when the product ships; it extends all the way to its final resting place.

Teach Your Customers How to Toss It

Once you’ve landed on the right material, your next job is to become an educator. Clear, simple disposal instructions are completely non-negotiable. If your beautiful new packaging is industrially compostable, you have to tell your customers exactly what that means.

Use clear icons and simple language right there on the packaging. A simple message like, "I'm compostable, but only at a special facility. Please don't toss me in your home compost or recycling bin," can make all the difference. That kind of clarity prevents contamination and ensures your investment in better materials actually pays off. For more ideas on shifting your product line, check out our guide and new zero-waste makeup products.

And for all of us shoppers? The plan is simpler but just as powerful. Get in the habit of looking for those official certification logos. Support the brands that give you clear disposal instructions, and take that extra second to put the packaging in the correct bin. It's those small actions, multiplied by millions of us, that create the real system-wide change we're all hoping for.

Got Questions About Biodegradable Plastics?

Jumping into the world of biodegradable plastics can feel a little confusing. It’s totally normal. As brands and consumers try to do the right thing, a few common questions pop up again and again. Let's clear the air on some of the biggest ones.

Answering these helps make sure the switch to biodegradable alternatives to plastic is actually making a difference. The goal is progress, not perfection, and that journey starts with good information.

Can I Just Toss Biodegradable Plastic in My Home Compost Bin?

This is a big one, and the short answer is almost always no. Most of the biodegradable plastics you see in packaging, like standard PLA, are pretty stubborn. They need the super-hot, specific conditions of an industrial composting facility to actually break down.

If you throw them into your backyard compost pile, they’ll likely just hang out for months or even years, not much better than regular plastic. If you want to compost it at home, you need to look for packaging with a specific "Home Compostable" certification, like the TÜV Austria OK compost HOME seal. When in doubt, always check the label for clear instructions.

So, Are Biodegradables Always a Better Choice Than Recycled Plastic?

Ah, the classic "it depends" situation. There's no easy winner here. On one hand, using recycled plastic (like rPET) is great because it keeps existing waste out of landfills and oceans, giving it a second life without drilling for new fossil fuels. It’s all about creating a circular system for the materials we’ve already made.

The "better" option really hinges on the product's entire lifecycle and, maybe most importantly, what kind of waste services are actually available where the customer lives.

Biodegradable plastics have the major advantage of coming from renewable sources, which is awesome. But they still have an environmental footprint—think land and water needed to grow the crops. Plus, if a compostable package winds up in a landfill, it can release methane, a potent greenhouse gas. So, it's a trade-off.

What's the Biggest Mistake Brands Make When They Switch?

The single biggest slip-up is getting excited about a new material but completely forgetting about what happens to it after the customer is done with it. A brand can pour money into a fantastic, certified compostable package, but their responsibility doesn't end when the product sells.

Think about it: if their customers don't have access to industrial composting, or if the disposal instructions are confusing (or missing!), that amazing material is probably headed straight for the landfill. Educating your customer isn't just a nice little extra; it is an essential part of making the system work.

At Axiology, we're all about making sustainable choices that are both clear and truly effective. Our commitment to being 100% plastic-free is a huge part of our mission to clean up the beauty industry. You can explore our collection of vegan, cruelty-free, and zero-waste makeup here.