When we talk about biodegradable packaging, we're talking about materials that can be broken down by nature's cleanup crew—microorganisms—and returned to the earth as simple things like water, carbon dioxide, and biomass.

Think of materials like plant-based plastics (PLA), molded pulp, and bagasse. They offer a totally different end-of-life story compared to traditional plastics, helping brands like ours dramatically cut down on long-term environmental clutter. This isn't just a nice-to-have anymore; it's what people expect.

Why Sustainable Packaging Is No Longer Optional

The whole conversation around packaging has flipped. What used to be just a box is now a billboard for a brand's values. It’s a physical manifestation of its commitment to the planet. For a beauty brand like Axiology, choosing biodegradable materials isn't a trend—it's a core part of our business strategy, driven by some seriously powerful forces.

The Rise of the Conscious Consumer

Shoppers today are smart, savvy, and more environmentally clued-in than ever. Get this: a staggering 82% of consumers say they're willing to open their wallets a little wider for sustainable packaging. That number jumps to 90% for younger generations.

This isn't just a fleeting preference. It’s a demand for brands to step up and be accountable. People are actively looking for companies that share their values, and packaging is the first, most tangible proof point they see.

The market is reflecting this loud and clear. The global biodegradable packaging market was valued at around USD 501.27 billion and is on track to hit a massive USD 876.05 billion by 2033. This kind of growth is a huge signal that this shift is being powered by both consumer demand and tougher environmental rules. If you're curious, Mordor Intelligence has a great report on global biodegradable packaging solutions.

Beyond Trends to a Circular Future

Switching to sustainable packaging is about so much more than keeping up with current demand. It’s about future-proofing our brand. This move is a huge piece of the puzzle in a much bigger shift toward embracing the circular economy, a system designed to keep materials in use for as long as possible and slash waste.

By choosing materials designed to return to the earth, brands can:

- Build real brand loyalty: Making eco-conscious choices creates a deep, lasting trust with your customers.

- Get a competitive edge: Doing good for the planet makes you stand out in a seriously crowded market.

- Make the product experience better: Thoughtful packaging turns the simple act of unboxing into a special moment, reinforcing the quality and care you put into your products.

This isn't just a reactive move; it’s a proactive step toward building a more resilient business. Brands that lead the way in sustainability are simply better prepared for whatever comes next—new regulations, supply chain curveballs, and what customers will want tomorrow. It’s a strategic investment in a healthier planet and a stronger business.

Understanding The Building Blocks Of Green Packaging

Diving into the world of biodegradable materials can feel a bit like learning a new language. But once you get the hang of the core options, you'll see they’re really just different tools for different jobs. Consider this your practical toolkit—we’re breaking down the most common materials into simple, understandable terms.

Think of it as a walkthrough of your workshop. We'll look at each material, exploring where it comes from, what it does best, and how it can bring your product's story to life. Let's get to know the building blocks that make sustainable packaging not just possible, but powerful.

PLA: The Plant-Based Plastic

Polylactic Acid, or PLA, is probably the most popular bioplastic you'll find today. Imagine a clear container that looks and feels like traditional plastic but is actually made from fermented plant starches—usually corn or sugarcane. It’s become a go-to in the eco-friendly packaging space for good reason.

Thanks to its clarity and rigidity, PLA is a fantastic substitute for petroleum-based plastics like PET. It’s often used for:

- Transparent containers: Perfect for showing off the gorgeous color and texture of a lip gloss or serum.

- Thermoformed trays: Ideal for creating those custom inserts that hold products securely in place.

- 3D printing filaments: A sustainable way to quickly prototype new packaging designs.

While PLA is a great start, it does have a catch: it typically needs an industrial composting facility to break down properly. That's a super important detail to share with your customers. If you're curious about other options, check out our guide on biodegradable alternatives to plastic.

PHA: A Marine-Safe Marvel

Polyhydroxyalkanoates, or PHA, is another bioplastic, but this one has a unique superpower. Think of it as PLA’s more resilient, ocean-loving cousin. PHA is created by microorganisms that produce natural, biodegradable polyesters.

The real magic of PHA is its ability to biodegrade in a much wider range of environments, including soil and even marine settings. This makes it an incredibly valuable tool in the fight against plastic pollution in our oceans. Its flexibility and durability make it great for things like films, coatings, and even straws.

Molded Pulp: The Protective Cushion

If you’ve ever opened an egg carton, you’re already familiar with molded pulp. Now, imagine that same concept, but elevated into a sleek, premium, and protective packaging solution for your beauty products. Made from recycled paper or renewable fibers like bamboo and sugarcane, molded pulp can be shaped into almost any form you can dream up.

This material is perfect for cosmetics because it provides excellent cushioning and can be molded to fit the exact shape of a bottle, jar, or tube. It also offers a raw, earthy aesthetic that communicates your brand's commitment to sustainability from the moment a customer opens the box. You can also delve deeper into sustainable cardboard packaging to understand similar eco-friendly options.

The push for materials like these isn't happening in a vacuum. It's a joint effort, driven by conscious consumers, forward-thinking brands, and new regulations all working together.

This map shows how everyone has a part to play in moving away from wasteful packaging. It’s a collaborative shift, not just a passing trend.

Cellulose: The Clear, Natural Film

Cellulose packaging comes from natural sources like wood pulp, cotton, or hemp. Think of it as nature’s transparent film. It's an excellent, eco-friendly alternative to plastic films and wraps because it’s fully biodegradable and compostable.

Its moisture-resistant properties have made it popular in the food industry, but it has some cool applications in beauty, too. It can be used for tamper-evident seals on jars or as a clear window in a paperboard box, letting your product peek through without relying on traditional plastic.

Bagasse And Starch Blends: The Upcycled Innovators

Some of the most exciting developments in biodegradable packaging come from upcycling agricultural waste. These materials give a second life to resources that would otherwise just be thrown away.

- Bagasse: This is the fibrous pulp left over after juice is extracted from sugarcane stalks. It’s then molded into sturdy, lightweight containers that are both microwave-safe and compostable.

- Starch Blends: Often made from corn or potato starch, these materials can be formed into things like packing peanuts or molded containers. They offer a non-toxic and biodegradable alternative to styrofoam.

The market for these materials is growing fast. Bio-plastics currently make up 51.0% of the biodegradable packaging material composition. Pouches and bags are the most common format at 26.0% of the market, and the food and beverage industry is the biggest user at 42.0%.

A Quick Comparison of Biodegradable Materials

To make things a little easier, here's a quick reference table comparing the key materials we've discussed. Use this to get a snapshot of their sources, best uses, and what to keep in mind for your brand.

| Material | Primary Source | Best For | Key Properties | End-of-Life |

|---|---|---|---|---|

| PLA | Cornstarch, sugarcane | Transparent containers, custom inserts | Clear, rigid, versatile | Requires industrial composting |

| PHA | Microorganism fermentation | Films, coatings, marine-safe applications | Flexible, durable, biodegrades in soil & water | Home compostable, marine biodegradable |

| Molded Pulp | Recycled paper, bamboo, sugarcane | Protective inserts, custom-fit packaging | Cushioning, moldable, premium, earthy aesthetic | Recyclable, home compostable |

| Cellulose | Wood pulp, cotton, hemp | Transparent films, window patches, seals | Clear, moisture-resistant | Home compostable |

| Bagasse | Sugarcane pulp (agricultural waste) | Trays, containers, clamshells | Sturdy, lightweight, heat-tolerant | Home compostable |

| Starch Blends | Cornstarch, potato starch | Loose-fill (packing peanuts), molded forms | Lightweight, dissolves in water | Home compostable |

Each of these materials has its own unique strengths. The goal is to find the one that not only protects your product but also aligns perfectly with your brand's values and your customer's expectations.

How to Match the Right Material to Your Product

Choosing the right biodegradable packaging isn't just about checking an "eco-friendly" box. It's about performance. Think of it like dressing for the weather. You wouldn’t wear a sundress in a snowstorm, and you wouldn't wear a parka to the beach. The packaging you choose has to be the perfect fit for your product's specific needs, its journey to your customer, and how it looks on their vanity.

Every single material has its own personality—its own set of strengths and weaknesses. Your job is to play matchmaker, lining up those properties with exactly what your product requires. This way, your product stays safe and effective, and you're telling a consistent sustainability story from start to finish.

Figure Out What Your Product Actually Needs

Before you can pick a material, you have to get real about what you're asking it to do. Every product has a list of non-negotiables to keep it safe, stable, and lovely to use. A quick reality check of these needs is the first step.

Start with these key questions:

- How much protection are we talking about? Does your product need a suit of armor to prevent shattering, or is a simple, flexible mailer enough?

- Does it need a barrier? Will things like moisture, oxygen, or even sunlight mess with the formula?

- What's the product's form? Are we dealing with a liquid, a solid powder, an oily balm, or a delicate bar?

- How will it get from point A to point B? Think about the entire trip, from your warehouse to a customer's mailbox.

Answering these creates a functional blueprint for your packaging. This blueprint becomes your guide, helping you sift through all the options to find the few materials that can actually get the job done right.

Pair the Material with the Product

Once you know what your product needs, you can connect those needs to the strengths of specific materials. Let’s make this real. A liquid foundation has totally different requirements than a pressed powder, so they're perfect examples of this matching game.

Scenario 1: Packaging a Liquid Foundation

A liquid foundation is sensitive stuff. It needs serious protection to prevent leaks and keep the formula perfect.

- Top Priority: A killer barrier. The packaging absolutely must keep the liquid in and the air out. Air can cause the formula to oxidize, which can mess with the color.

- Also Important: Durability. The container has to be tough enough to handle being dropped or squeezed during shipping and everyday use.

- Good Material Matches: You could look at PLA lined with a compostable coating, or even glass with a molded pulp shell. The PLA gives you structure, while a special barrier coating keeps the foundation stable. An outer shell from molded pulp can add that extra cushion for shipping.

Scenario 2: Packaging a Pressed Powder

A pressed powder, like a blush or eyeshadow, is super fragile. Its biggest enemy? Impact.

- Top Priority: Impact resistance. The packaging’s number one job is to cushion that delicate powder cake and keep it from cracking into a million pieces.

- Also Important: A secure closure. A flimsy clasp means the compact could pop open in a purse, creating a glittery, pigmented mess.

- Good Material Matches: Molded pulp is a total superstar here. It can be custom-molded into a snug clamshell that absorbs shock like a champ. For the compact itself, something like compressed bagasse or even wood can feel sturdy and look beautiful.

When you break down your product’s vulnerabilities and needs, you stop guessing and start problem-solving. It ensures the biodegradable materials you choose are more than just a green statement—they're a functional part of your product that keeps it safe and makes your customers happy. After all, the best sustainable choice is the one that actually works.

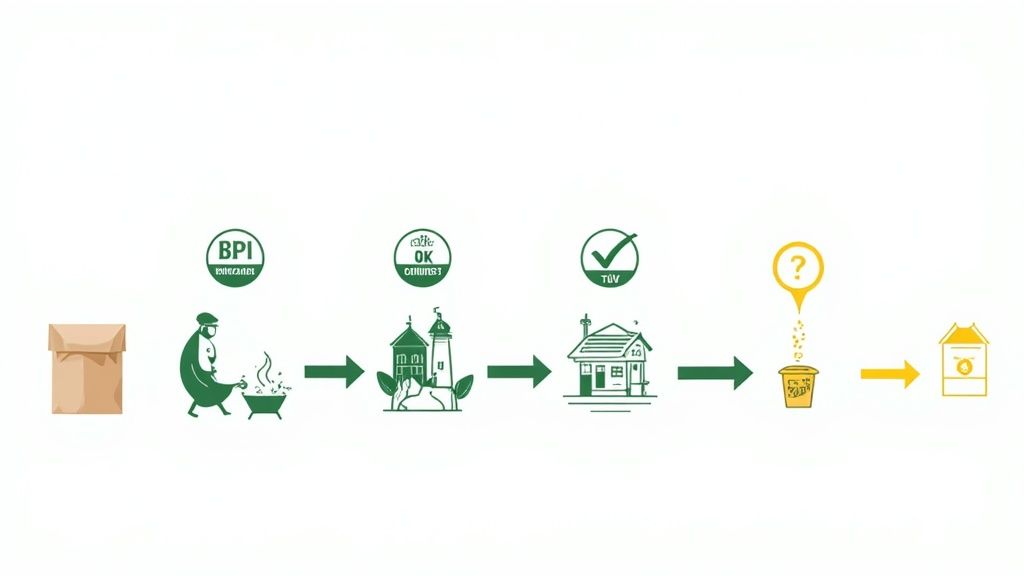

Making Sense of Certifications and Disposal

Let's be real: navigating eco-friendly claims can feel like trying to read a map without a key. Words like "biodegradable" and "compostable" get thrown around a lot, but without proof, they’re just noise. This is where certifications come in.

Think of them as a seal of approval from a trusted third party. They’re what tells you—and your customers—that your packaging actually does what it claims. For us, it’s proof of our commitment. For you, it’s a sign of integrity, cutting right through the greenwashing.

Decoding the Seals of Approval

When you spot a certification logo on a package, it means the material has passed a whole series of tough scientific tests to prove how it breaks down. These organizations set the global standards, ensuring that "compostable" materials decompose within a specific timeframe without leaving any nasty stuff behind.

Navigating the different logos can be tricky, so here’s a quick guide to the major players you'll see.

Understanding Key Eco Packaging Certifications

| Certification Logo | Certifying Body | What It Means | Primary Region |

|---|---|---|---|

| BPI Logo | Biodegradable Products Institute (BPI) | This is the gold standard in North America. It confirms a product is safe for industrial composting. | North America |

| OK compost HOME | TÜV AUSTRIA | A highly sought-after seal verifying a product can break down in a backyard compost pile. | Europe / Global |

| OK compost INDUSTRIAL | TÜV AUSTRIA | This logo means the material is certified for the high-heat conditions of an industrial facility. | Europe / Global |

| Seedling Logo | European Bioplastics | A common mark across Europe indicating compliance with the EN 13432 industrial composting standard. | Europe |

These certifications aren't just for show. They’re crucial for being transparent and helping everyone make the right call when it’s time to toss the packaging.

The Realities of End-of-Life Disposal

Okay, so choosing a certified material is a huge step. But it’s only half the battle. The other half is making sure the packaging actually gets to its proper "end of life." This is where the story gets a little more complicated.

Most bioplastics, like PLA, need the specific, high-heat environment of an industrial composting facility to properly break down. These facilities are basically supercharged compost piles, maintaining the perfect mix of temperature, moisture, and oxygen—conditions that are almost impossible to get right in a backyard bin.

The big challenge? Access to these industrial facilities is still pretty limited in many parts of the country. This means even a perfectly certified compostable package could end up in a landfill, where it won’t biodegrade as it should. It’s a reality gap we all have to consider.

Home vs. Industrial Composting

Getting the difference between home and industrial composting is key. It’s a bit like baking a cake.

Imagine home composting as trying to bake a cake using just the heat from a sunny window. Sure, it might eventually work for simple things like veggie scraps, but it’s a slow, low-heat process. It just doesn’t have the oomph for denser, more complex materials.

Industrial composting, on the other hand, is like a professional convection oven. It has the precise, high-heat controls needed to break down tougher stuff—like bioplastics—quickly and completely.

This distinction is everything. It dictates the disposal instructions we give and requires total transparency about what’s possible. It's about empowering customers to close the loop correctly.

For brands that want to take full responsibility, offering take-back programs is a powerful solution. To see how we handle our hard-to-recycle items, you can find inspiration and learn how to recycle your tubes with our own program. It’s one way to help bridge the infrastructure gap and make sure these great materials are handled properly.

When you're making choices for your brand, it helps to zoom out and see the bigger picture. The move toward biodegradable packaging isn't just a niche trend; it's a global movement, and it looks a little different everywhere you go. Understanding what's happening in various parts of the world is key to making smart moves that align with both regulations and customer values.

Think of it like this: what gets people excited in Europe might be totally different from what motivates shoppers in North America or Asia. By tuning into these different frequencies, you can create a packaging strategy that really connects.

How The World Is Tackling Packaging

A quick look around the globe shows that different regions are adopting sustainable packaging for very different reasons and at very different speeds. Europe, for example, is way ahead of the curve. Their market for biodegradable packaging is expected to jump from USD 4.2 billion to USD 7.1 billion by 2035. A huge part of that is Germany, which holds a whopping 31.2% market share, thanks to some pretty comprehensive laws.

Meanwhile, North America makes up 36.0% of the global market, but the push here is more about brands wanting to meet consumer demand and get ahead of environmental rules. You can get more of the nitty-gritty details in this regional packaging report from Future Market Insights.

Here’s what’s really driving the change in these key areas:

-

Europe is all about rules. The government is leading the charge with big-picture policies like the EU's Green Deal. They're setting serious goals for reducing waste, which pretty much forces brands to get creative with biodegradable options.

-

North America is led by shoppers. While new regulations are definitely a factor, the real pressure in the North American market comes from us—the consumers. More and more people want eco-friendly options, so brands are voluntarily stepping up their game to stay competitive.

-

Asia Pacific is growing fast. In places like the Asia Pacific region, rapid growth and a rising awareness of environmental issues have created a huge demand for sustainable alternatives. As concerns about plastic pollution grow, both governments and consumers are looking for better solutions.

What does this mean for a brand like ours? It's huge. In Europe, the conversation might be all about meeting regulations and being part of a circular economy. In North America, it's more about connecting with customers over shared values, like protecting our planet.

Keeping an eye on these global trends is about more than just picking a material. It’s about building a packaging strategy that's not just sustainable but also smart. It helps you see where the world is heading and ensures your products feel right at home, no matter where they're sold.

Your Action Plan for Adopting Biodegradable Packaging

Okay, so you get the theory behind biodegradable materials. But actually making the switch can feel like a massive leap. The good news? It doesn’t have to be.

The trick is to break the process down into clear, manageable steps. Think of it less as one giant task and more as a series of strategic decisions. This is your practical playbook for turning a big goal into an achievable reality for your brand.

By focusing on one step at a time—from finding the right partners to looping in your customers—you can build a sustainable packaging strategy that's both effective and genuinely you.

Find and Vet Your Suppliers

Everything starts with a great supplier. You need a partner who not only has high-quality biodegradable materials for packaging but also lives and breathes your commitment to transparency and sustainability. Don't be shy about asking the tough questions.

Start by making a shortlist of potential suppliers and do a little digging:

- Ask for certifications: Can they show you proof of compostability or biodegradability from legit organizations like BPI or TÜV AUSTRIA?

- Request material samples: You have to see and feel the materials. Do they meet your standards for quality and aesthetics?

- Inquire about sourcing: Where do their raw materials come from? Is everything sourced ethically and sustainably?

- Discuss minimum order quantities (MOQs): Make sure what they require actually works with your production needs and budget.

A true partner will be an open book, ready to hand over documentation and answer your questions clearly. This whole vetting process is your best defense against greenwashing and the only way to ensure the materials you pick are the real deal.

Collaborate on Design and Budgeting

Once you've found a supplier you vibe with, it’s time for the fun part: collaboration. This is where you bring your vision to life, ideally working with designers who have experience with sustainable materials. They get the quirks and limits of things like molded pulp or PLA and can help you create a design that's both stunning and functional.

This is also the moment for a frank conversation about money. Yes, sustainable materials can sometimes cost more upfront, but a savvy design partner can help you find ways to be efficient.

- Go for minimalism: Can you use less material without sacrificing protection?

- Right-size your packaging: Getting rid of empty space cuts down on material use and shipping costs.

- Budget for the long game: The initial investment might be higher, but it can pay off big time in brand loyalty and customer trust. A whopping 73% of consumers say they're willing to pay more for sustainable packaging.

Educate Your Customers on Disposal

Your job isn't done once the product is out the door. To truly close the loop, you need to show your customers how to properly dispose of the packaging. Clear, simple instructions on the package itself are non-negotiable.

Use straightforward icons and simple words to explain what to do. Is it "Home Compostable"? "Industrially Compostable"? "Recyclable"? This clarity turns your customers into active partners in your mission. For a deeper dive, our guide on biodegradable packaging for cosmetics has more specific tips just for beauty brands.

Follow this plan, and you can confidently make the switch to sustainable packaging, making choices that are good for your products, your customers, and our planet.

We Get It, You Have Questions

Diving into the world of sustainable packaging can feel a little overwhelming, and it always brings up some great questions. Getting straight answers is the only way to feel good about the choices you make for your brand. So, let's tackle some of the most common things we hear about biodegradable packaging.

Is Biodegradable Packaging Actually More Expensive?

This is the big one, right? While some cutting-edge bioplastics can cost more upfront than your standard plastic, it's definitely not a universal rule. Materials like molded pulp and kraft paper are often right on par with conventional options. It helps to think of it less as an expense and more as an investment.

That investment often pays for itself in customer love and brand reputation. With a whopping 82% of consumers saying they'd pay more for sustainable packaging, any initial cost difference can be quickly balanced out by stronger sales and a loyal following who truly values your commitment to the planet.

What’s The Real Difference Between Biodegradable And Compostable?

This is such a crucial distinction, and a place where a lot of greenwashing happens. Biodegradable is a super broad term. It just means a material can be broken down by microorganisms over some period of time. It doesn't say how long or under what conditions.

Compostable, on the other hand, is a specific, regulated term. For a material to be certified compostable, it has to break down into natural elements in a composting environment within a set timeframe (usually 90-180 days) without leaving any toxic stuff behind. Here's the key: all compostable materials are biodegradable, but not all biodegradable materials are compostable.

Can I Just Toss All Biodegradable Packaging In My Backyard Compost?

Nope, and this is where things can get confusing for everyone. Many bioplastics, like PLA, need the intense, sustained heat of an industrial composting facility to properly break down. They'll just sit there in your typical backyard compost pile for ages.

Materials like untreated paper, bagasse, and molded pulp are generally good to go for home composting. To be absolutely sure, you should always look for a "Home Compostable" certification, like the one from TÜV AUSTRIA's OK compost HOME.

The Takeaway: The end-of-life plan for a package is just as important as the material it's made from. If your packaging needs an industrial facility but your customers don't have access to one, its eco-friendly benefit pretty much disappears.

How Do I Explain Proper Disposal To My Customers?

Clarity is everything. You can't assume your customers are packaging experts. Use simple, direct language and easy-to-understand icons on your packaging to show them the way.

Here are a few ways to do it right:

- Use Clear Icons: Simple, recognizable symbols for "Recycle," "Home Compost," or "Industrially Compost" work wonders.

- Provide Simple Text: A quick, friendly instruction like, "Please compost this box, but remove the label first," makes a huge difference.

- Educate on Your Website: Set up a dedicated page that explains your packaging choices and what to do with each piece when it's empty.

When you make disposal instructions easy to find and follow, you're not just selling a product; you're inviting your customers to be part of the solution.

At Axiology, we believe in making choices that are kind to your skin and the planet. Explore our collection of plastic-free, vegan makeup designed for the conscious consumer at AxiologyBeauty.com.